Current Projects

Current Project > Civil/InfrastructureRoad

Tipping the balance for mine restoration and waste recycling

16 July 2024

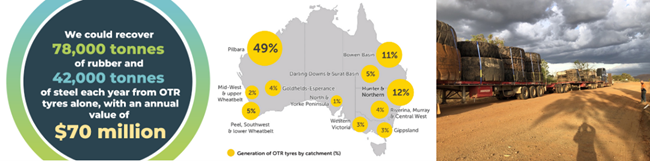

In November 2023, the recovery of 800 tonnes of used Off-The-Road tyres and conveyor belts from a remote region in Western Australia is the first of its type and magnitude undertaken in Australia.

It provides a real-world demonstration of the possibilities of a circular economy for big rubber product users, such as the Mining industry.

It is also an example of how collaboration between recyclers and rubber product users can move through perceived barriers to viable solutions for used Off-The-Road (OTR) tyres, conveyor belts and tracks that would otherwise go to waste.

1 The end goals

Not your average road

This road, on the Sunshine Coast in Queensland, is more resilient to tough environmental conditions, lasts longer than standard bitumen and reduces waste.

Why? Because it’s made with crumb rubber from used Off-The-Road (OTR) tyres and conveyor belts that are built to last in tough conditions.

Roads like this will be constructed from over 800 tonnes of used OTR tyres and conveyor belts recovered from Rio Tinto’s Argyle Diamond Mine in Western Australia.

The mine was closed in 2020 and is now being rehabilitated for return to the Traditional Owners – the Miriwoong and Gija people.

The goal is to preserve ecological and cultural heritage values, ensure a smooth transition for the local community and support potential future activities, such as:

- cattle grazing,

- cultural tourism,

- cultural use, and

- possibly small-scale agriculture and native food production.

New life for old tyres

Rather than go to waste in licensed landfills or stockpiles or be exported for use in other countries, the valuable rubber products from this project have been collected and processed by Townsville-based Carroll Engineering Services for use in Queensland roads.

This circular economy partnership between Rio Tinto and Carroll Engineering Services converts waste rubber into value for government, industry, business and communities, creating commercial opportunities, new jobs and new products made in Australia for Australians.

Used tyres, conveyor belts and tracks are some of the most challenging waste streams for the mining industry to deal with.

In searching for a solution, the Rio Tinto Closure, Procurement, Argyle Site and Projects teams had stringent criteria that looked beyond simply removal to recovery, reuse and market demand for the end product.

Carroll Engineering Services, accredited by Tyre Stewardship Australia, was awarded the contract as it was able to:

- process used rubber products into crumb that can be used to build new roads and other products,

- meet Rio Tinto’s due diligence requirements, and

- demonstrate effective risk management in undertaking this circular economy project.

It’s the first time a recovery of this type and magnitude has been undertaken in Australia; and provides us with a real-world demonstration of the possibilities of a circular economy for big rubber product users, such as the Mining industry.

2 The Innovators

Rio Tinto, making it happen

Rio Tinto is committed to finding better ways in how the company operates and that includes improving its waste management practices and recycling wherever possible.

In an effort to reduce waste and landfill disposal, the Rio Tinto Closure, Procurement, Argyle Site and Projects teams investigate alternative options and identify suppliers with technology capable of recycling waste tyres and conveyor belts for end-market use.

The November 2023 trial will inform the recovery of used rubber products from other Rio Tinto sites.

Carroll Engineering Services, getting it done

800 tonnes of used mining tyres and conveyor belts to be collected from the closed Argyle Diamond Mine in East Kimberley?

No problem for the team at Carroll Engineering Services.

It took 15 road trains running in triples and travelling 3,200 kilometres, and back again, to collect the tyres and belts.

The epic job didn’t end there. Carrol Engineering then processed the used products to create hundreds of tonnes of high-quality crumb for infrastructure construction in Queensland.

The councils and businesses building roads of the future

Off-the-road (OTR) rubber products are tough and built for demanding conditions, so it’s no wonder road builders, like councils and asphalt producers around Australia are harnessing their performance qualities to build more resilient roads and, in doing so, reducing waste for future generations.

In Queensland, Sunshine Coast Council is trialling the right mix of rubber binder and asphalt for optimum performance in low to high traffic conditions. The trial is a joint endeavour with regional businesses: Boral and its subsidiary Allens Asphalt; Carroll Engineering Services; and Puma Energy Bitumen. It is being led by the Australian Flexible Pavement Association (AFPA) with support from RMIT University and Tyre Stewardship Australia.

They are providing a real-world example of how a ‘circular tyre economy model’ can enable rubber products used by industry in regional, rural and remote areas to be reused.

The potential benefits for local communities and industries are far-reaching: from the reduction of used tyres remaining in unrecovered or low-value outcomes to economic advantages such as the creation of local jobs, business opportunities and regional development.

3 The challenge

Breaking down barriers to the safe recovery of one of Australia’s most valuable resources

Off-The-Road (OTR) tyres that have reached their end of life are one of the biggest challenges for mining companies.

They’re built to last and are often located in remote areas so distance can be seen as a costly challenge.

But the cost:benefit equation starts tipping the return on investment scales when viewed in a circular economy framework and you see the value at the other end.

That’s exactly what the Rio Tinto Closure, Procurement and Project Management teams did to find a better way to remove the 800 tonnes of used tyres and conveyor belts from its closed Argyle Diamond Mine site in Western Australia.

The task was made possible through rigorous logistics planning in collaboration with Carroll Engineering Services.

In doing so, they took Australia one step closer to a circular economy for Off-The-Road (OTR) tyres and conveyor belts.

No mean feat, considering the existing school of thought that there are too many challenges to overcome, such as:

- the low perceived costs of on-site disposal,

- the high costs of logistics and recovery,

- uncertainty about technologies and waste management approaches,

- uncertainty about end market size and capacity, and

- a low priority for tyre waste stewardship.

It is a real-world demonstration of how collaboration between OTR rubber product users and recyclers can move through perceived barriers to solutions for the recovery and reuse of waste rubber products.

Rio Tinto continues to investigate alternative options for managing its waste. It is applying circular thinking through understanding technology options and end-market uses, whilst enhancing its procurement practices.

What’s stopping us?

The challenges for Australian tyre recyclers in recovering used off-the-road (OTR) rubber products are big. But so are the opportunities.

That’s why waste tyre recyclers, like Carroll Engineering Services, are expanding their services into regional, rural and remote areas to tap into the value of recovering and processing rubber products used in mining and agriculture.

In undertaking this trial, Carroll Engineering not only recovered valuable resources for use in building roads but also helped Rio Tinto:

- apply its strong commitment to ESG best practices to its tyre and belt waste,

- undertake a test of technologies and practices that can be used to recover used rubber products from other remote sites, and

- assess the feasibility of recovery across distances and facilities.

It‘s a real-world example that challenges tyre recyclers to take another look at the opportunities in a circular economy context that could make the distance worthwhile:

- Is the volume there to make recovery of value to end markets, such as local government?

- Are there opportunities to extend procurement contracts beyond the removal and licensed disposal of used rubber products?

- Can smaller tyre recyclers work together to leverage rubber products in key catchment areas?

- What technology is needed to process large mining tyres and other rubber products?

4 The result

What you are seeing is a high-quality construction material, made from 800 tonnes of used Off-The Road (OTR) tyres and conveyor belts, that can help build more resilient roads, pavements and other community infrastructure.

This is the end result of the partnership between Rio Tinto and Carrol Engineering Services that converted waste rubber products into valuable construction material – made in Australia for Australians.

The crumb, produced by Carroll Engineering Services, will help build new roads in Queensland.

It is being purchased by local construction, engineering and energy businesses such as:

- Puma Bitumen

- Fulton Hogan

- RPQ Group

- Bituminous Products

This is circular economy thinking in action with far-reaching environmental and economic advantages such as reduced waste and the creation of jobs, business opportunities and regional development in Australia for:

- Local communities in regional, rural and remote areas

- Manufacturing

- Infrastructure builders such as local, State and Federal governments

- Waste recyclers and processors

Find out more about what used OTR rubber products can do for your industry and your community

- Tipping the Balance Report into off-the-road tyres, conveyors, and tracks

- A path forward for stronger collaboration with Indigenous Peoples and Local Communities to accelerate tyre resource recovery in regional, rural and remote Australia

- Circular tyre economy Projects and Case Studies

- Closing the Argyle Diamond Mine

- Rio Tinto Sustainability – Safe and Responsible Asset Closure

- Carroll Engineering Services – Turning end of life tyres into valuable resources

- A first for Queensland – Council builds roads of the future

- Talk to the TSA Market Development team – email getonboard@www.tyrestewardship.org.au

@RioTinto #FindingBetterWays

@CarrollEngineering #TurningEndOfLifeTyresIntoValuable Resources

@TyreStewardshipAustralia #TippingTheBalance #CircularTyreEconomy

@AllensAsphalt

@AustralianFlexiblePavementAssociation

@BituminousProducts

@Boral

@FultonHogan

@PumaBitumen #EnergisingCommunities

@PumaEnergyBitumen

@RMITUniversity

@RPQGroup

@SunshineCoastCouncil