Latest News

TSA News > Australia’s largest council-led recycled rubber road project paves the way for environmental and economic results

Australia’s largest council-led recycled rubber road project paves the way for environmental and economic results

7 May 2024

Australia’s largest council-led recycled rubber road project paves the way

The Southern Sydney Regional Organisation of Councils (SSROC) led one of Australia’s largest multi-council demonstration projects, using rubber recovered from end-of-life tyres blended into bitumen to enhance asphalt durability, performance, and environmental sustainability of road pavements. Conducted by RMIT University, a Life Cycle Assessment entitled Life Cycle Assessment and Potential Environmental Benefits of Crumb Rubber Asphalt using Field Data has studied the environmental impacts associated with incorporating recycled rubber from end-of-life tyres into bitumen for asphalt pavement construction and has found that recycled rubber extends

pavement service life, reduces demand for raw materials and lowers environmental impacts.

Led by SSROC with the support of Tyre Stewardship Australia (TSA), and in partnership with the Australian Flexible Pavement Association (AfPA), the Paving the Way: Recycling Tyres for Roads project involved: Bayside, Burwood, Canada Bay, Canterbury-Bankstown, City of Sydney, Georges River, Inner West, Randwick, Sutherland, Waverley and Woollahra and Northern Beaches councils. In 2023, the 12 participating councils each resurfaced a road using a recycled rubber-modified asphalt mix. Of the demonstration sites, three – in Burwood Council, City of Sydney and Northern Beaches Council areas – were selected for an in-depth investigation into the potential environmental benefits of using rubber-modified bitumen in council asphalt roads.

The comprehensive Life Cycle Assessment assessed the carbon footprint (kg CO2- equivalent) and other environmental impacts of production, construction, and maintenance of recycled rubber asphalt pavements compared to conventional asphalt mix (without recycled rubber) laid at the same location and exposed to comparable traffic and weather conditions. The study found that incorporating recycled rubber into asphalt mixes using the wet method (crumb rubber assimilated into bitumen at high temperature to produce a modified polymer) can reduce environmental impacts during the production and construction phase compared to conventional asphalt. By adding 10% crumb rubber by weight of the total binder (100 grams of crumb rubber to 900 grams of virgin bitumen to manufacture 1 kg of rubber-modified binder) resulted in lower environmental impacts compared to using 1 kg of conventional bitumen, leading to reduced emissions during the construction phase.

The assessment considers existing research that has demonstrated improvements in pavement performance due to rubber-modified asphalt needing fewer maintenance interventions during the service life, consequently reducing environmental impacts (up to 30%) associated with the maintenance phase of the road asset. It also demonstrated indirect environmental benefits, such as recovering steel from end-of-life tyres during crumb rubber production and diverting waste tyres from landfills, which will further decrease greenhouse gas emissions associated with using rubber-modified asphalt. SSROC President and Mayor of Burwood, Councillor John Faker said “Using crumb rubber in asphalt pavement construction and maintenance, operations makes a substantial contribution to low-carbon infrastructure, minimising long-term maintenance costs, maximising performance, and promoting a more sustainable approach.”

RMIT Civil and Infrastructure Engineering Professor, Filippo Giustozzi explained that “The calculations done by RMIT University regarding project-level environmental impacts at SSROC councils have demonstrated that incorporating crumb rubber into asphalt roads using the wet method holds significant promise for reducing the total carbon footprint of these roads by up to 30% throughout their service life. This can potentially offset the environmental impacts generated by new road construction and ongoing maintenance operations, therefore contributing to the decarbonization of the road infrastructure.”

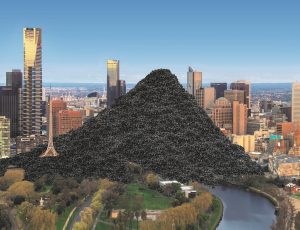

AfPA Executive Director Technology and Leadership, Anna D’Angelo said, “This project is a great example of circular economy. Using crumb rubber from end-of-life tyres can help Australia cut down on the more than 450,000 tonnes of waste tyres generated annually. The use of crumb rubber in asphalt increases the performance and durability of the roads while fostering a more sustainable waste-to-resource approach.”

TSA Chief Executive Officer, Lina Goodman said “Paving the Way demonstrates the value of crumb rubber in asphalt. Not only does it offer performance benefits to extend the roads’ life and increase performance, but crumb rubber also reduces carbon emissions and environmental impacts. Using crumb rubber in roads is a key way Australia can derive value from end-of-life tyres in the circular economy.” The extended service life and reduced environmental impacts underscore the importance of incorporating recycled materials, like recovered crumb rubber, in asphalt for sustainable infrastructure development.

Read the Full LCA Report here

Media release originally published by SSROC