Latest News

TSA News > Mining Magazine: Steering clear of a linear economy

Mining Magazine: Steering clear of a linear economy

6 June 2023

Adopting circular economy practices in the mining industry does not only refer to the on-site practices of employees and mining corporations, but also extends to include responsible management of the waste streams the industry produces. While the spotlight has certainly shifted to illuminate environmentally friendly practices like proper tailings storage, and more recently recycling mining uniforms, end-of-life (EOL) tyres is the latest waste stream undergoing upheaval.

In late 2022, Federal Minister for Environment and Water, Tanya Plibersek, pinpointed tyres as one of three waste streams on the Federal Government’s annual priority list. This brought necessary attention to the lagging rates of used tyre recovery, particularly for OTR (off-the-road) tyres, effectively putting the industry on notice.

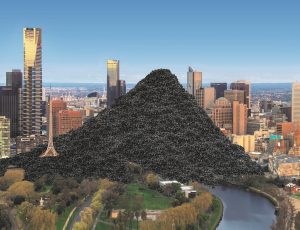

The Department of Climate Change, Energy, the Environment and Water estimates that more than 130,000 tonnes of mining, agriculture and aviation tyres reach end of life each year, with a mere eleven per cent being recovered. On top of this, approximately 80,000 tonnes of additional related products, like rubber tracks and conveyor belts, are currently not being sustainably managed each year.

These EOL tyres often end up buried in-pit or dumped on land, resulting in significant environmental, health and safety hazards. The sheer magnitude of this waste stream and the dangers of improper waste management has underscored the need for product stewardship schemes and an increase in processes to recycle EOL tyres.

Read more here.