Latest News

TSA News > TSA and Clark Rubber Collaboration

TSA and Clark Rubber Collaboration

1 November 2023

Rubber Soul: New Collaboration Aims to Revolutionize Australia’s Tyre Waste Problem

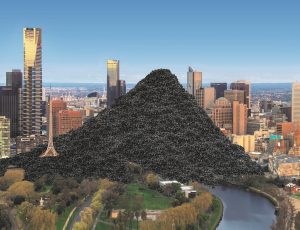

Every year, a staggering 500,000 tonnes of tyres in Australia reach the end of their road, and shockingly, only a mere 15% of these materials are currently being repurposed in Australia. The rest are either exported overseas as fuel replacements or are stockpiled, dumped, or landfilled, contributing to an environmental challenge of immense proportions.

Tyre Stewardship Australia (TSA) is committed to finding solutions for tyre-derived material in Australia; through its market development fund, with grants up to $250,000 available to organisations who need the extra support to commercialise their innovations or products containing used tyres.

TSA’s market development fund is not new, but what is new is the collaboration with Clark Rubber, Australia’s only national retailer dedicated to selling all things “rubber.” This collaboration lends itself to opportunities of in-store product promotion and the commercialisation of value-added rubber products that may be suitable for the Australian market.

TSA and Clark Rubber are calling out to Australian manufacturers, innovators, entrepreneurs, polymer experts and other relevant businesses who can demonstrate how rubber from used tyres can be used as an ingredient in new products – and if you need a kicker to get this across the line, TSA has made its market development fund available for applicants.

CEO of TSA, Lina Goodman, emphasizes the significance of this opportunity, stating, “This collaboration, supported by the TSA Market Development fund is a clever opportunity for Australians to create high-performance rubber products that align with Australia’s goals for a circular economy.”

“We would love to see more products on our shelves that include Australian recycled tyre materials, and the TSA fund is a fantastic way for manufacturers to get financial support to do this. We can’t wait to see the great new ideas that are generated” says Clark Rubber CEO Anthony Grice.

Australia currently lags behind countries like Denmark, France, and Canada, which are effectively utilizing their excess tyre stockpiles. However, businesses like A1 Rubber are leading the way in repurposing these end-of-life tyres for a range of innovative purposes, including mats for gyms, utes and vans, rubber tiling and pavers, wet pour rubber and much more.

A1 Rubber’s CEO, Tim Ekert, shared insights into their journey, saying, “We started 30 years ago, driven by the idea that tyre rubber is too valuable to discard, investing in this notion right from our backyard.”

Their product portfolio is diverse, encompassing flooring, retail-focused home gym tiles, vehicle protective mats, and acoustic underlays for high-rise buildings, along with soft fall surfaces for children’s playgrounds, all made from repurposed tyre rubber.

Ekert further elaborated on the scale of the issue, “When we talk about 500,000 tonnes of tyres, we’re referring to end-of-life car, bus and truck tyres, far more than A1 Rubber can consume. At A1 Rubber we upcycle approximately 8,000 to 9,000 tonnes of tyres each year, there is room for more manufacturing using local high-quality tyre-derived polymers.”

When asked about potential product ideas, Ekert emphasized the versatility of rubber and its natural properties, including slip resistance and shock absorption, which can be harnessed to create a wide range of sustainable and functional items.

Reflecting on the impact of such funding, Ekert noted, “Commercializing new ideas is often the most challenging step. Market development and sales experience are vital. We’ve learned how to utilize rubber’s unique properties, and we support TSA wherever we can.”

TSA, in collaboration with businesses like Clark Rubber and A1 Rubber, is not only pushing for a circular economy but also addressing an issue that has long been exported rather than resolved locally. This initiative is not just about reusing materials; it’s about creating innovative, sustainable solutions right here in Australia.

For more information about the Tyre Stewardship Australia Market Development Fund:

- Email funding@tyrestewardship.org.au

- Visit TSA Fund Guidelines and Application page to find out more.