Latest News

TSA News > Turning trash into treasure: How Australia’s tyre stewardship initiative must pave the way for a circular economy

Turning trash into treasure: How Australia’s tyre stewardship initiative must pave the way for a circular economy

23 March 2023

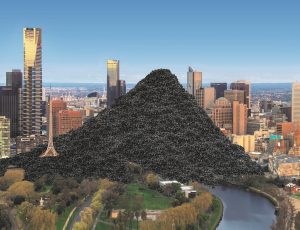

Each year, 450,000 tonnes – the equivalent of 56 million passenger tyres – reach their end of their life in Australia, often ending up in landfill or stockpiles that can take centuries to decompose. An eyesore on the side of roads and in our natural spaces, dumped tyres also pose significant environmental and social challenges.

Less than 20 per cent of tyre material is processed and recycled into ‘value-added products’ (meaning transformed into new materials of greater value) in Australia. At the same time, a staggering 135,000 tonnes are sent to landfill or buried, stockpiled or dumped each year. What Australia doesn’t use onshore in value-added products is exported for reuse or as an alternate fuel.

A staggering 135,000 tonnes are sent to landfill or buried, stockpiled or dumped each year.

But the winds of change are blowing. In November last year, Environment Minister Tanya Plibersek announced tyres as one of three waste streams on the government’s annual priority list, effectively placing the industry on notice.

“The priority list makes our intentions clear – if industry does not act, the government will,” Ms Plibersek said in a statement.

The concept of product stewardship involves all stakeholders in the product supply chain, including manufacturers, retailers, consumers, and government, playing their part across the entire lifecycle of a product, from its design and manufacture, to use, reuse, recycling, and safe disposal.

While industry-led product stewardship initiatives exist, not enough businesses participate, the government said. The makers and importers of items on the product stewardship priority list must take responsibility for the impacts of their products on the environment across their entire life cycle.

Tyre Stewardship Australia (TSA) was established in 2014 to implement the national Tyre Product Stewardship Scheme and find sustainable outcomes for used tyres.

“As a voluntary scheme, it can only go so far,” says the CEO of TSA, Lina Goodman. “The Minister’s priority list is a clear signal to industry – it is time to get serious about circular economy for used tyres in Australia.”

Ms Goodman says tyres – once regarded as ‘single use’ products, can now be reprocessed and used as raw material across various categories like construction, civil engineering, advanced manufacturing or fuel replacement.

“It excites me when I see Australian companies remanufacture the rubber polymer created from used tyres and create new and better-performing products, that can be sold and reused again, and again,” Ms Goodman says. “Crumb rubber from used tyres is a valuable feedstock for irrigation pipes, gym flooring, roads, golf courses and much more. It means creating local jobs and building Australia’s manufacturing sector. Imagine all of this is being created from your worn-out tyres.

The circular economy breaks away from the traditional, linear manufacturing process that sees materials extracted, used, and thrown away. Instead, it embraces a ‘closed-loop system’ to reuse and regenerate resources continually.

Already, Australia has made significant strides in demonstrating the potential for used tyres to become a valuable resource in the circular economy, in rubberised asphalt for roads, noise wall barriers, and agricultural mats.

Rubberised asphalt that recovers valuable resources from old tyres and turns them into new roads with a longer life expectancy.

John Gertsakis, director of the Product Stewardship Centre of Excellence, says adopting the circular economy is crucial in achieving a zero-waste society.

“Single-use products become a thing of the past in many cases,” he says. “We need to consume differently to conserve these finite resources by designing-out waste and pollution and keeping them circulating in the economy and reducing our carbon emissions by shifting to renewable resources and energy.”

Mr Gertsakis says companies, including manufacturers, importers, brands and retailers, are uniquely placed to make the circular economy a reality by being responsible product stewards.

“After all, the private sector designs, specifies, procures, distributes and sells products and constructs buildings and infrastructure,” he says.

He also suggests consumers can send manufacturers, brands and retailers “a very clear message” by prioritising products, services, and buildings that have proof of being part of the circular economy.

“Consumers and the general public have an important role to play in the circular economy through responsible purchasing and consumption,” he says. “They can also seek out products that contain renewable materials, are free of toxic substances and contain recycled content.”

When consumers choose an accredited local tyre retailer, they are helping turn their old tyres into new value-added products

Additionally, Mr Gertsakis says, consumers can buy less, choose well, and make things last through better service, maintenance, and repair.

When it comes to extending the life of your tyres, it pays to adopt good maintenance practices, such as checking tyre pressure regularly, rotating tyres regularly, and replacing them only when necessary.

When tyres need to be changed, Ms Goodman says it’s crucial to check your old tyres are managed responsibly. Australians can search the My Tyres My Choice online directory of accredited retailers who have agreed to adhere to the scheme’s guidelines for the responsible management of end-of-life tyres.

“If I needed to get my tyres changed, I would jump on My Tyres My Choice, I would find my closest retailer, then I can have confidence that that retailer is engaging an accredited tyre processor to take their used tyres and process them in a sustainable manner,” Ms Goodman says.

“And when choosing new tyres, choose those brands that have stepped up and are contributing to the Scheme, and helping to find new markets for your old tyres. That’s important, too.”

Original article posted here.