Latest News

TSA News > We need to start building for a harsher environment

We need to start building for a harsher environment

14 June 2023

Recycled materials like crumb rubber from used tyres can help Australians build hardier structures better suited for harsh environments.

Stanlake Avenue looks like any other quiet street in Mitcham, South Australia. But a subtle difference separates this 335-metre stretch of suburbia from other roads.

Rather than using a conventional asphalt mix, the City of Mitcham paved the avenue with crumb rubber asphalt. This material replaces part of the bitumen binder typically used in an asphalt mixture with granular crumb rubber sourced from recycled used tyres.

Roughly 850 tyres – enough for more than 200 cars – went into Stanlake Avenue, according to Tyre Stewardship Australia (TSA), who supported the trial through its Market Development Fund.

But it’s not just recycling for recycling’s sake. This crumb rubber asphalt can do everything conventional asphalt can, only better.

Building for tomorrow

Part of the reason behind this push for hardier, more resilient materials is the sense extreme weather is becoming a norm rather than an exception.

Australia is no stranger to challenging conditions, but last year’s record-breaking east coast deluge tested even the most resilient, washing away homes, businesses and community facilities.

The 2022 State of the Climate report, conducted by the Bureau of Meteorology and CSIRO, forecasts more of the same in the future.

The report predicts ongoing changes to Australia’s weather, including, climate variability that will give rise to short-duration heavy-rainfall events at a range of timescales.

A changing environment means industries will need to think and build differently.

Using alternative materials that can better cope with climate variability, such as those recovered from used tyres, is one of the ways industries and businesses can work smarter and build better.

Creating a circular economy

Using materials sourced from recycled tyres not only enables Australia to build for harsher environments, but to also recover valuable materials from the abundance of used tyres that we discard each year.

Australia is in the world’s top 10 countries for vehicle usage per capita, according to TSA, with an estimated 20 million vehicles – or 85 million tyres – on the road.

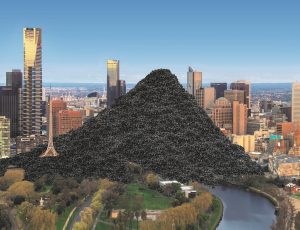

As a result, Australia generates around 459,000 tonnes of tyre waste annually.

Of this, an average of 330,000 tonnes are recovered and repurposed. But that still leaves more than 100,000 tonnes of tyre waste sent to landfill, illegally stockpiled or dumped.

Finding new uses for old tyres is a no-brainer for Rose Read, Director of the Product Stewardship Centre of Excellence, an organisation that helps industries become better product stewards.

A lot of resources go into making tyres,

Ms Read said. There’s a lot of rubber and steel and various fabrics and so on. And there’s a lot of carbon, which we call embodied carbon, in those products. It’s really important that these materials stay in the productive economy and circulate in the economy, rather than being dumped into landfills or in the back of paddocks where they become an environmental risk.

Making something fit for purpose

The crumb rubber asphalt in the Stanlake Avenue trial is a great example of recycled materials achieving better outcomes in a challenging environment.

Mitcham is notorious for its highly reactive clay soils. Because of the movement, new roads often have to be resurfaced after two to five years. But the crumb rubber asphalt provides a better way forward.

The City of Mitcham observed improvements in longevity, performance and crack resistance, with crumb rubber asphalt lasting almost four times longer than standard mixes.

Recent research from RMIT, led by Associate Professor Filippo Giustozzi, supports these observations. A lab test on UV protection ‘found that the ageing trend is actually slowed down when you add crumb rubber, which is recycled from used tyres, into the top layer of a road,” Giustozzi said. “This acts so effectively as a sunscreen for roads that it actually makes the surface last twice as long as regular bitumen’.

Another good example has been created by Porous Lane, a Melbourne-based business.

The company worked with Melbourne University and TSA to develop a permeable footpath that allows water to pass through, rather than run off to the side.

The key to this design was the addition of crumb rubber granules from recycled tyres. The material increases the flexibility of these surfaces, making them durable and resistant to cracking.

Porous Lane’s permeable pavement is ideal for footpaths, driveways and parking lots that see a bit of rain, putting less pressure on drainage networks and decreasing the likelihood of flash flooding. And the best part? The company has diverted more than 5,000 used tyres from landfill.

Finding smarter solutions

Changing and challenging conditions put the onus on organisations to think differently about what they’re doing. Procuring smarter materials, such as those sourced from recycled tyres, is one way local councils and communities can build to withstand a harsher environment.

Australian inventor and entrepreneur, Gary Bullock from Flexiroc Australia, has developed a blast and ballistic concrete product made from recycled tyres. Mr Bullock said that the “concrete-like material is designed to meet the challenges of Australia’s harsh environments, while also adding safety, security and extreme loading resilience.”

Several major infrastructure and transport projects have already been earmarked to showcase Flexiroc’s innovative product – providing further opportunities and benefits for Australia’s circular economy.

Ms Read was keen to highlight just how important these projects are for our environment.

We only have a finite number of resources on this planet and we do need to use them wisely in terms of how we consume those products,

she said.

If we can reduce the number of raw materials and virgin materials we’re using at the front end and make those products and materials and infrastructure and buildings last longer, we’re getting a much better return on investment.

Original article posted here.