TSA publishes its research report into off-the-road tyres, conveyors, and tracks

After more than two years of industry-led research and consultation, Tyre Stewardship Australia has published its report into the use, recovery, and recycling of Australia’s off-the-road tyres, conveyors, and tracks (OTR rubber products).

OTR rubber products are critical for the Australian economy. Up to 245,000 tonnes are used and become waste each year, with around 80% of this coming from the mining sector and 10% from agriculture. Regrettably, the vast majority is buried on site, stockpiled, or sent to landfill. But used rubber products are a valuable resource, and finding a new life for them offers many environmental, social, and economic benefits, particularly in regional and remote Australia. The Report was funded by the Australian Government’s National Product Stewardship Investment Fund and TSA, which provides a pathway forward for Australia to realise the benefits of OTR tyre, conveyor and track resource recovery, particularly in regional, rural and remote areas.

Australia's options for recovering resources from OTR rubber products are not going to get any clearer or easier. This report provides the evidence. It's time to accept that evidence, think about the future we want, and act on the choices we can make today.

The Report was funded by the Australian Government’s National Product Stewardship Investment Fund and TSA, which provides a pathway forward for Australia to realise the benefits of OTR tyre, conveyor and track resource recovery, particularly in regional, rural and remote areas.

At a glance

Tipping the balance

Entitled Tipping the balance – the business case for a circular economy for Australia’s off-the-road tyres, conveyors, and tracks, the report is a thorough analysis of the current state of OTR rubber product use, recovery, and recycling in Australia. It defines the barriers causing persistently low recovery rates of about 10%, and begins evaluating the opportunities to address these barriers to increase resource recovery and recycling.

The report defines where we are now, and focusses on what we can do to improve the recovery and recycling rates of OTR rubber products. The how we do it is the next step, and this report provides a solid foundation on which Australia can build world-leading recovery solutions, learning from and improving on recovery schemes in Denmark, Canada, Chile, France, Italy and, soon, New Zealand.

The issues and the opportunity

TSA’s CEO Lina Goodman said:

“This report makes it clear that Australia’s persistently low resource recovery rate for OTR rubber products is simply not good enough.”

The report identified 5 key barriers, including:

- the low perceived costs of on-site disposal,

- the high costs of logistics and recovery,

- uncertainty about technologies and waste management approaches,

- uncertainty about end market size and capacity, and

- a low priority for tyre waste stewardship.

Of these, the low cost of on-site disposal is the key issue, largely because the mining sector is permitted to bury tyres on-site for free due to licensing exemptions.

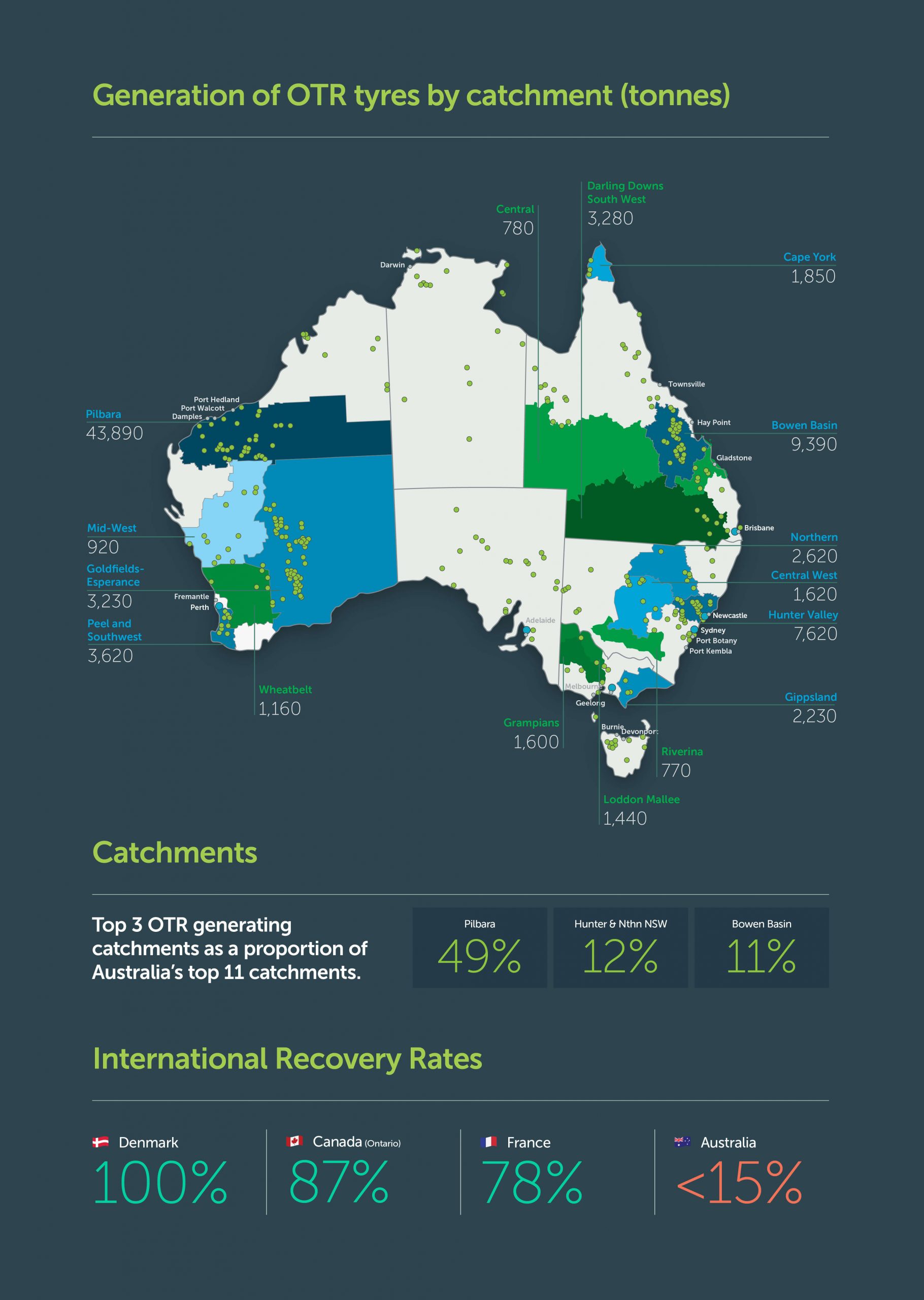

There are several regions, or catchments, that generate most of Australia’s used OTR rubber products, with unique barriers and opportunities in each of these ‘catchments’. The report recommends that further engagement and collaboration with local mining and agriculture stakeholders, government, and indigenous people and local communities in these key catchments is a priority to finding real-world solutions which can be easily transferred as a blueprint for catchments across the Australia

It’s time to move

“This report is a step change that can take Australia from being a country that literally buries its used OTR tyres, conveyors and tracks to a world leader in recovery and recycling”, said Goodman.

“Every business that creates, uses or disposes of an OTR rubber product must become responsible stewards of its lifecycle. There is no silver bullet solution, and waiting for one is no longer good enough. We must take progressive steps now towards a circular economy for OTR rubber products.”

“Change like this doesn’t happen overnight, but now is the time to act, because with this report we know enough to step forward confidently. The world has moved on and we need to move with it. We can’t bury our heads in the sand about onsite dumping of OTR rubber products anymore.”

The challenge

“Our first step is to reconsider the current voluntary Tyre Product Stewardship Scheme,” said Lina Goodman, “at the moment we don’t have the authorisation to support the supply chain for OTR rubber products that Australia needs.

“A second step is to engage all the parties involved in supplying, using, and recovering OTR rubber products, and the various other stakeholders who are affected by or have a say in the way these products are used.

“I’m talking about tyre manufacturers, wholesaler and recyclers, mining and agricultural companies, governments at all levels, researchers, and indigenous people and local communities. I encourage them all to read this report and understand the implications and opportunities it identifies. Ignoring this report and failing to take action will only compound the existing issues and exacerbate this already lost opportunity.”

Making an impact

This report has already begun a process of positive collaboration and change, and this work continues to build a roadmap to increase OTR rubber product recovery rates.

In January 2022, OTR tyre importers including Ascenso, Bearcat, Bridgestone Mining Solutions, Goodyear, Kal Tire, Michelin and Yokohama joined the voluntary Tyre Product Stewardship Scheme, contributing a levy on every OTR tyre sold into the Australian market to create more sustainable outcomes at their end of life.

Mining companies across Australia shared their knowledge and experience to support this research report. Several mining companies have been equally enthusiastic to find solutions for this problem and priority waste, collaborating with TSA real-world demonstrations and market development activities, as well specific support to deal with legacy OTR rubber products issues at their mines.

Engaging with stakeholders from agriculture and aviation sectors, indigenous peoples and local communities and government, as well as the conveyor belt and tracks manufacturers and importers is ongoing as we continue to consider and test ways to increase recovery rates, develop end markets for tyre-derived material and learn from procurement, fitment, maintenance, repair and disposal models.

Catchment-level engagement and research is underway in the priority regions – Pilbara, Northern NSW and Bowen Basin. And several TSA-funded market development projects and trials looking specifically at the OTR rubber products or their use in end-markets are underway with more in the pipeline.

“We will continue to work across the value chain, government and indigenous communities and local communities to advocate for changes that will reduce barriers and encourage investment in the sector, fund research and market development and collaborate with all stakeholders responsible for the stewardship of OTR rubber products.”

Download the report

Tipping the balance summary and action plan

Download Summary