Current Projects

Current Project > Civil/InfrastructureRoad

Stronger, Smarter Roads: Sunshine Coast Council’s 12-Month Results Using Crumb Rubber from Off-the-Road Tyres

13 February 2025

In 2024, Sunshine Coast Council launched a demonstration project to test the use of off-the-road (OTR) tyre-derived crumb rubber in road construction and repairs. Now, 12 months on, the results are in—and they reveal a promising future for this innovative material.

The project not only confirmed that crumb rubber from OTR tyres can replace traditional crumb rubber in bitumen blends and asphalt mixes, but also provided valuable technical data on performance, constructability, and durability. The findings offer a roadmap for councils across Australia to adopt this untapped resource and build longer-lasting, cost-effective roads.

Key 12-Month Findings at a Glance

✅ Proven Durability: OTR crumb rubber-modified bitumen shows that OTR crumb rubber can be used interchangeably with traditional crumb rubber without requiring significant adjustments in asphalt production or placement.

✅ Constructability Validated: The trial demonstrated that OTR crumb rubber can be used interchangeably with traditional crumb rubber without requiring significant adjustments in asphalt production or placement.

✅ Circular Economy in Action: By sourcing and processing tyres locally, Sunshine Coast Council closed the loop on a local waste problem while creating new economic opportunities.

Who should know about this?

- Local, State, Territory and Federal Government building roads.

- Waste Tyre Collectors and Recyclers seeking new revenue streams.

- Mining and Agriculture using off-the-road tyres.

- Manufacturers adopting and adapting emerging technology for recycling.

- Researchers & Developers investigating the science of waste reduction.

- Indigenous Peoples and Local Communities seeking commercial opportunities.

The Project in Detail

Goals

The demonstration project aimed to answer several critical questions about the feasibility and benefits of using OTR crumb rubber in road construction:

➡️ Can OTR crumb rubber replace traditional crumb rubber in bitumen blends and asphalt mixes?

➡️ How do crumb rubber asphalt mixes perform in real-world conditions?

➡️ What are the lifecycle and cost benefits compared to conventional asphalt?

➡️ How can local councils tap into waste-to-resource streams and reduce disposal challenges?

The Innovators

The project was a collaborative effort involving key partners:

- Australian Flexible Pavement Association (AfPA) former Executive Director Anna D’Angelo led the project.

- Sunshine Coast Council provided the demonstration sites and technical application oversight.

- Boral provided the tyres from their local quarry + its subsidiary Allens Asphalt provided operational delivery as part of its supply and lay contract with Sunshine Coast Council.

- Carroll Engineering Services processed the tyres into crumb rubber.

- Puma Bitumen manufactured the CRM bitumen.

- RMIT University – Civil and Infrastructure Engineering undertook accelerated aging assessments led by Associate Professor Filippo Giustozzi

- TSA Market Development Fund contributed $99,000 to support the project.

The Challenge

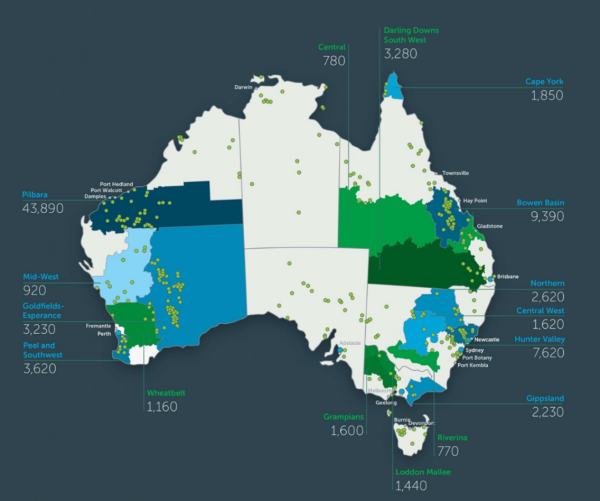

Across Australia, less than 15% of OTR tyres are recovered—compared to 100% in Denmark, 87% in Canada, and 78% in France.

OTR tyres are built to endure tough conditions, making disposal a significant challenge for industries like mining and agriculture. Their resilient construction, size, and remote locations often result in low-cost onsite burial or stockpiling, creating environmental and social risks for local communities and wasting valuable economic opportunities.

Recycled rubber from passenger car, bus, and truck tyres has been used in road construction for decades, but this was one of the first trials to explore crumb rubber from OTR tyres, commonly used in mining and agriculture.

This challenge represents a significant opportunity for Australian local councils, particularly those in 11 catchment areas identified as high-value generators of used OTR tyres. Sunshine Coast Council became the first in Queensland to take up this challenge for the benefit of all councils seeking circular economy solutions to local waste problems.

Source: TSA Tipping the Balance Report 2024

The Solution

In 2024, Sunshine Coast Council partnered with the Australian Flexible Pavement Association and Boral Asphalt to design a demonstration project that generated data on the constructability and performance of Crumb Rubber Gap Graded (GGA) mixes using crumb rubber manufactured from 100% OTR tyres.

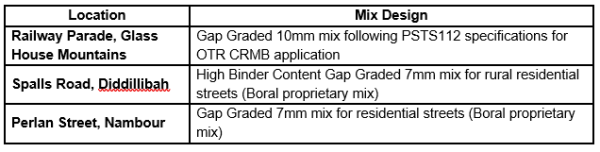

Three test sites, representing different traffic levels and three different mix designs, were selected:

The Results: 12 Months On

The trial successfully demonstrated that crumb rubber derived from OTR tyres can be used interchangeably with traditional crumb rubber without requiring significant adjustments.

Spalls Road, Diddilibah – before, during and after construction

Key findings include:

✅ The modified binder was less susceptible to ageing from exposure to UV radiation and retained a more elastic response after ageing, leading to greater resistance to environmental cracking and longer road durability when compared with conventional bitumen.

✅ All the binder properties for the crumb rubber modified bitumen satisfied the requirements of the Austroads Technical Specification (ATS) 3110 for A18R, except for segregation. A significant amount of clumping was identified on the surface of the binder after 48 hours of conditioning at 180 °C. This issue can be addressed by modifying the blending method and/or by adding compatibilisers. Additional operational measures associated with storage and handling of the binder, along with careful planning/timing of delivery of works, can minimise segregation during construction.

The AfPA’s report, ‘Creating opportunity for increasing the use of Off-the-Road (OTR) tyres derived crumb rubber in roading applications’, provides further data and is available for download below or via the AfPA website.

The project offers valuable technical insights for other councils in regions where OTR tyres are used, providing them with a pathway to leverage this resource for the benefit of their communities.

A Circular Economy in Action

The trial demonstrated circular economy principles at a local level. By sourcing used OTR tyres from Boral’s local quarry, processing them through Carroll Engineering Services, and incorporating the material into council roads, the project created a closed-loop system.

This localised approach highlights how councils can collaborate with industry partners to convert challenging waste streams into high-value construction materials while reducing environmental impacts and creating economic opportunities.

Looking Ahead

The success of this trial positions Sunshine Coast Council as a leader in sustainable road construction. Councils across Australia can build on these findings to adopt similar solutions, improving road performance and supporting a circular economy.

#ReinventingTheWheelForGood

#TSAMarketDevelopmentFund

#MarketDevelopment

#RecycledTyres

@AustralianFlexiblePavementAssociation

@Boral

@AllensAsphalt

@PumaBitumen

@CarrollEngineering

@RMITUniversity

Learn More

- Download AfPA’s report on ‘Creating Opportunity for Increasing the Use of OTR Tyre Derived Crumb Rubber in Roading Applications’

- TSA News – A first for Queensland: Council builds ‘roads of the future’

- Other TSA case studies

- TSA Tipping the Balance for Off The Road tyres in Australia Report

- Sunshine Coast Council Waste Recovery Strategy 2023

- Sunshine Coast Council When the rubber hits the road https://els.sunshinecoast.qld.gov.au/discover-by-location/when-the-rubber-hits-the-road

- Boral Big tyres making a big difference https://www.boral.com.au/big-tyres-making-big-difference