Life Cycle Assessment of end-of-life tyres

What is a Life Cycle Assessment?

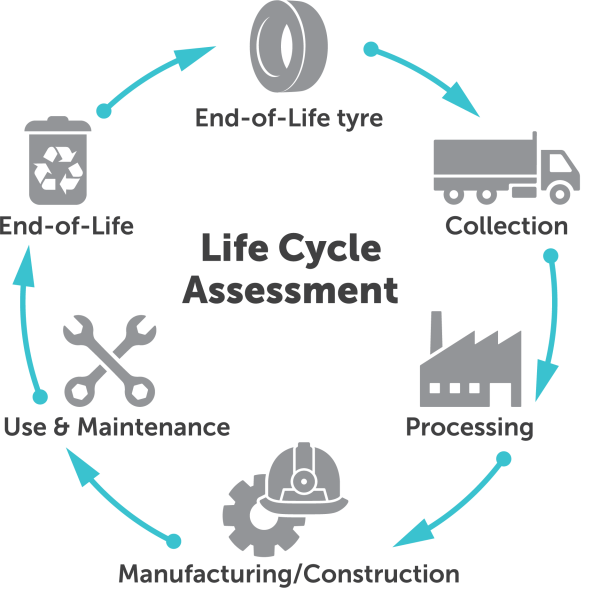

When you manufacture a product, that process will have an environmental impact on the planet. One way to determine the scale of this impact is to complete something called a Life Cycle Assessment (LCA).

LCAs are useful because they offer a holistic view of the environmental impacts of a product or service throughout its entire life cycle. They can cover different life cycle stages, from the extraction of raw materials, manufacturing, use, all the way to end-of-life management outcomes.

A LCA can gather data on aspects like resource consumption, carbon emissions, water usage, and the use of recycled materials and translate this data into impacts, known as Environmental Impact Categories.

What are the benefits of a Life Cycle Assessment?

Knowing the life cycle impacts of a product can highlight the benefits of using certain products over others, due to a reduction in emissions.

LCAs can also demonstrate where an organisation can make improvements on the environmental impacts of a product or service. A business could then use LCA data to identify an impact hotspot in the life cycle of their product, and work on scenario planning and actions to reduce or avoid this impact.

Tyre Stewardship Australia LCA Research

TSA has worked with LCA experts, Edge Impact, to research and develop industry-wide LCA data and information relating to end-of-life tyres.

Life Cycle Assessment of End-of-Life Tyres:

The initial study assesses the environmental impacts of several tyre-derived products produced from passenger and truck tyres (shred, granules, and crumb rubber) and common end-markets (such as roads and infrastructure).

The study considers many scenarios and compares the environmental impacts of tyre-derived products, with several scenarios demonstrating a reduction in impacts when compared to conventional products.

Life Cycle Assessment of Agriculture and Mining Off-the-Road (OTR) Tyres:

The recovery of OTR tyres is notably lower compared to other tyre types. Challenges in recovering OTR tyres include differences in handling and transportation, insufficient recovery services, and conflicting priorities among involved parties.

Given these differences, it is difficult to directly apply existing strategies and data from passenger and truck tyres, and as the result the environmental benefits from the recovery of OTR tyres is less researched and unclear.

This second study aims to begin filling this knowledge gap, by considering different recovery pathways of OTR tyres through the lens of a LCA, to determine the differences in environmental impacts. Five different recovery pathways were assessed, two for agriculture tyres and three for mining tyres, which were separately compared and evaluated to identify the optimal scenarios for recovery in each case.

How can we use these Life Cycle Assessments for end-of-life tyres?

The above two projects involved significant collaboration across the entire tyre value chain, connecting the dots between various stages of the tyre management pathway, to provide an industry benchmark on end-of-life tyre recovery. Open access to baseline and independent LCA data on tyre recovery is critical for the future of the industry as it will allow organisations to:

- more easily quantify the environmental impacts and benefits of a product or service,

- conduct further analysis unique to a business or process,

- support both market development and sustainable procurement,

- promote strategies to improve and reduce the impacts and emissions throughout the value chain.

There have been previous LCAs completed that consider the environmental impacts of tyre-derived materials, however, the process of collecting life cycle data can be time-consuming and resource-intensive. This may limit the ability of a business to gather all the relevant data to complete an accurate LCA of their product.

More FAQs

LCA information is highly regarded and can be used in many ways, such as:

- Providing data to develop Environmental Product Declarations (EPDs).

- Providing data for Regulatory Compliance.

- Providing data for Public Project Tenders.

- Providing data for Sustainable Procurement.

- Enabling Manufacturers to compare different materials for resource efficiency.

- Allowing industry to identify inefficiencies and areas for resource optimisation to reduce waste, energy consumption, and material costs.

Yes, there are standards for LCA methodology, such as ISO 14040:2006 which has been used as the basis of the above research.

Even following international standards such as this, other published LCA data relating to tyre-derived products may not be directly comparable due to varied methodological choices, different data sources, and different geographical and temporal considerations.